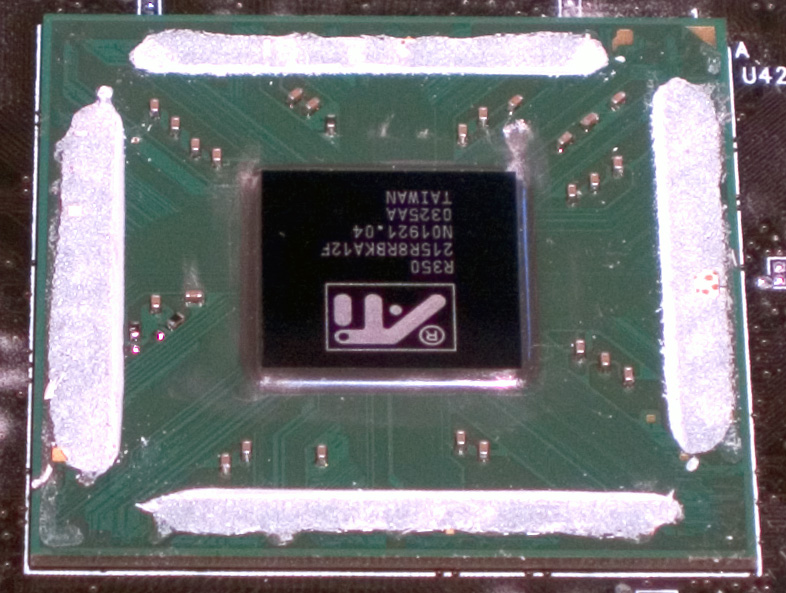

This is how the VPU core looks after a good cleaning, and ATi's shim removed;

you can see the leftover materal on the packaging where the metal frame was.

aPPLYING

tHERMAL

iNTERFACE

mATERIAL...

...the NgTechnik Way!

I

decided to write up a brief little article on a good method of applying TIM

(thermal interface material). For this article, I used the Radeon 9800 and an

Iceberq 4 heatsink. The pictures came out a little off-colored due to my

little lighting experimentation (wanted to see how much I can compensate with

the automatic settings in RAW mode to deal with my peculiar, "white," light

lamp), but for reference I am applying Arctic Silver V using a plastic spoon.

Step One: Clean your surfaces...

I use 70% isopropyl alcohol to clean my heatsink and core

surfaces:

This is how the VPU core looks after a good cleaning, and ATi's shim removed;

you can see the leftover materal on the packaging where the metal frame was.

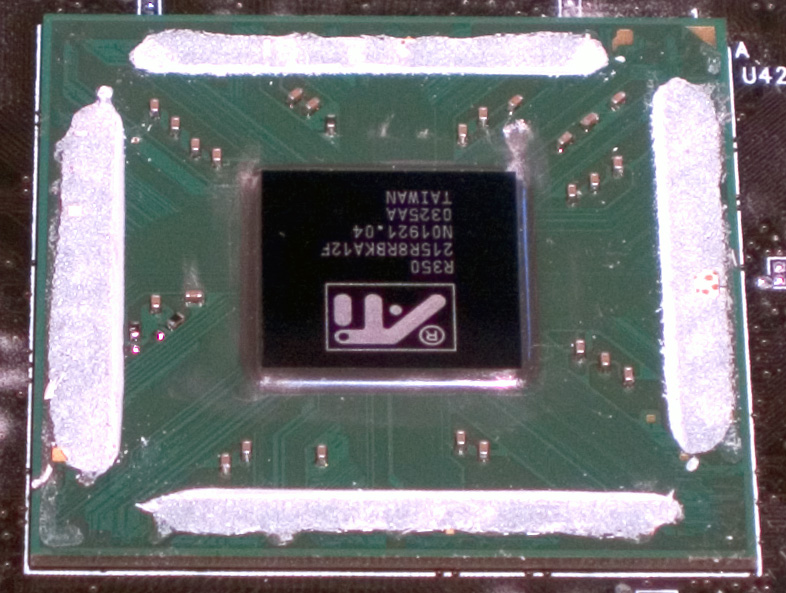

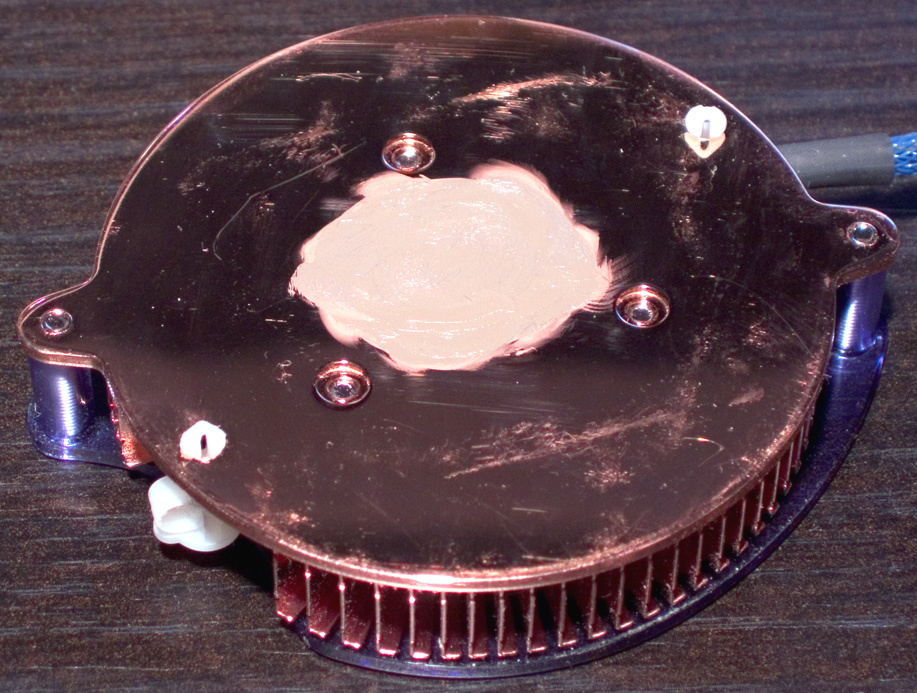

This is how the bottom of my Iceberq 4 looks after cleaning.

It comes from the factory with a mirror smooth finish; the scratches are my own

fault

(I know, I know--stupid move. Live and learn, as they say...).

The Iceberq 4 normally is clean and faultless.

Step Two: Apply a minimalist amount

of TIM to the center of the sink...

Use a firm, smooth tool that has been cleaned properly just

like the core and the heatsink; again, I personally use a plastic spoon that I

completely dispose of after use; for reference,

I utilized a total volume of less than 1/2 grain of North Carolina long-grain

rice worth of TIM across both surfaces

(I only squeezed out TIM once, on the sink, and used the leftovers from the

spoon for the core!!!). PLEASE NOTE that that amount is for THIS chip!

For a chip with heatspreader like P4 or K8, you must use more and for something

with a tiny die like Thoroughbred, you might use less; use your sensibility to

judge; with practice, it will become more natural. I apply the thinnest possible layer of material to both

surfaces as part of my technique:

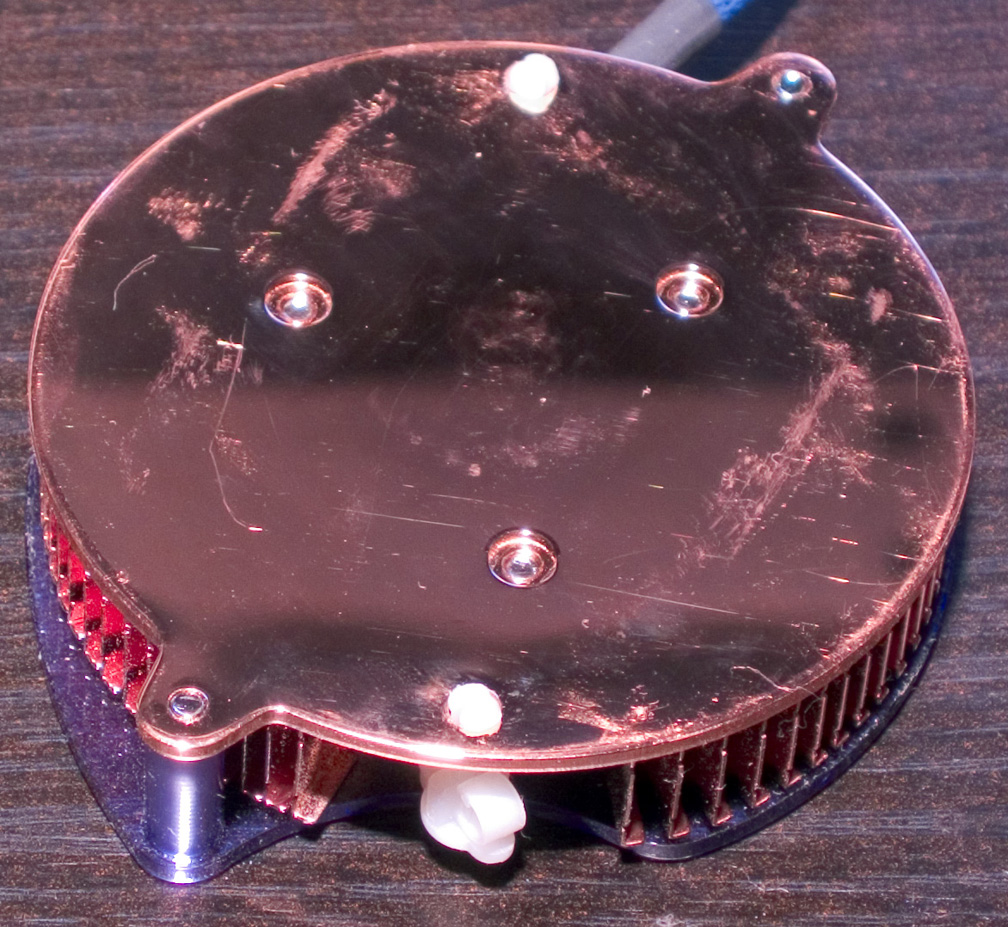

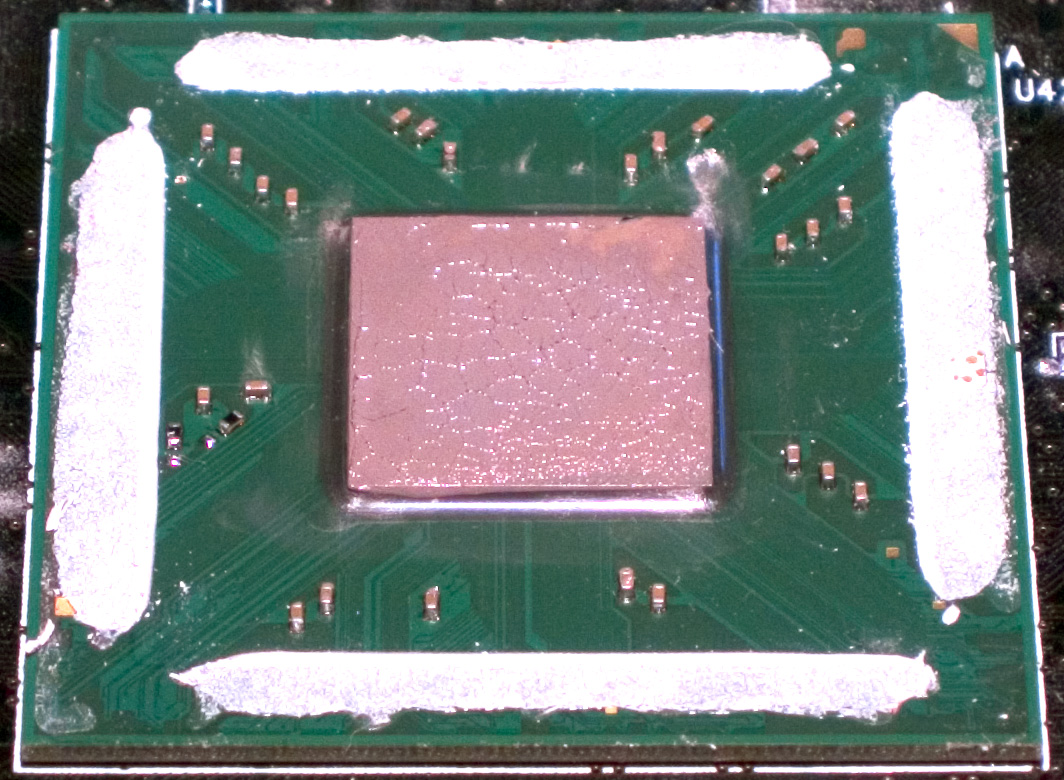

Here is the VPU core after my application of TIM...

I place a minute amount of TIM to the center and use a spreading motion out to

the edges,

like spreading butter on toast. Just like spreading butter on toast, you

put just enough and spread away,

but you don't want excessive overflow at the lip; that would make a greasy mess

of breakfast! Excess material should be,

"lifted," off and away, not just spread off the core to dribble down the

edge; excess is less of a problem for myself and will be same

for you once you've practiced this style of application enough. You

can actually see the pattern of my motions across the surface

if you look carefully enough. For this example, actually, I squeezed a minute

amount onto the sink, did my spread job on it,

and then did this core using only the residual

TIM left on my spoon from doing the sink!

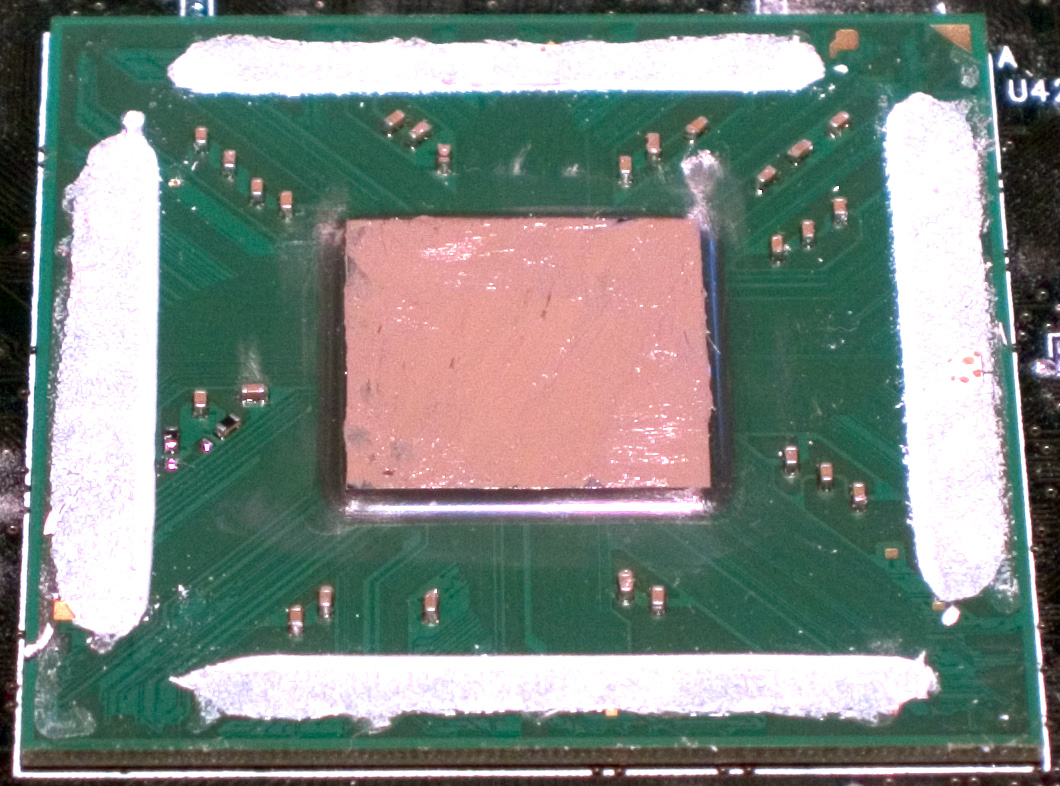

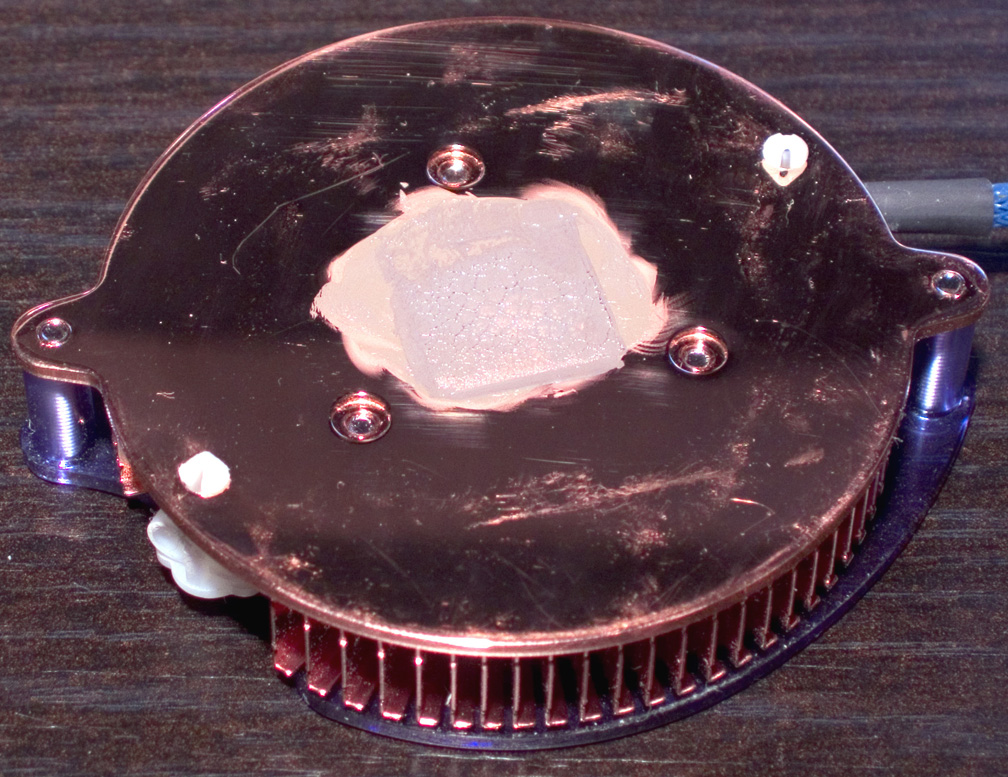

Now we have the bottom of the heatsink. Instead of the, "butter-spreading,"

style I use on the core,

I apply extremely heavy pressure with my plastic spoon and go in a circular

motion in order to spread it out as thinly as possible.

This is the reason why I use a plastic spoon instead of something metal; if I

applied it my way with a metal tool, I would scratch the sink,

and that would be an extreme no-no!

You can just make out my circular motions; the TIM fades

off at the edges, it's so thin.

Step Three: Install the sink...

While I firmly believe the virtually perfect application of

the virtually perfect amount of TIM is sufficient for the absolute optimum

effect (nothing in existence is absolutely, positively

perfect perfect

![]() ),

I still like to use a special motion when installing the sink. I place the sink

on top of the chip, align it so that it's in a position that's exactly as it

will be once firmly clipped on, then apply a small amount of force and do a

couple back and forth two to three degree twists, to ensure the tightest

possible seal and to be 100% sure that there is

absolutely no excess TIM:

),

I still like to use a special motion when installing the sink. I place the sink

on top of the chip, align it so that it's in a position that's exactly as it

will be once firmly clipped on, then apply a small amount of force and do a

couple back and forth two to three degree twists, to ensure the tightest

possible seal and to be 100% sure that there is

absolutely no excess TIM:

This is how the TIM looks on the VPU after I install the sink and remove it

(for inspection or, in this case, to show you guys). The very, very fine little

peaks

that come up prove that it was extremely close to the perfect amount of TIM. If

there's lots of excess,

when you pull your sink away, the resulting, "streaming spikes," would be

larger--picture cheese pizza, piping-hot out of the brick oven.

Here's the opposite side, underneath the sink. Again, notice just how little

excess TIM is left rising or streaming away from the surface.

I would like to add that for that last step, the amount of

pressure I apply to squeeze the sink down to the chip varies on the application.

For Pentium 4 or chips with heatspreaders over them, I apply a little more

pressure, particularly if the mainboard is not installed yet; I can place my

hand underneath the board and the other hand holding the sink--if the

motherboard is installed already, I use much less pressure so as not to damage

the mainboard. For bare cores that are BGA packaging, I apply less pressure than

on chips with heatspreaders, like I did for this VPU in my example. Finally, for

very sensitive chips like the Socket A chips, which are bare cores with nothing

underneath to support them (there is the hollow center of the socket underneath,

which has been cause to many broken Athlon packages), I apply extremely minor

pressure, certainly no more pressure than the heatsink itself will be applying

once installed.

If you were linked here from SilentPCReview.com, you can click here to return to the home page.

Please point all comments and inquiries to Edward Ng.